Modern stockbreeding is the activity highly polluting the environment when high harmful CH4, N2O and NH3gas contents are emitted into the atmosphere. Anaerobic digestion of organic waste significantly reduces harmful methane gases in their content. The most effective way to manage organic wastes, such as manure of cows, pigs and poultry,on the farm isanaerobic digestion technology when biogas is generated. Agricultural biogas is the gas that is produced during the anaerobic digestion as well as the digestion of the combination of animal waste and agricultural product, which can be used as fuel for gas engines in cogeneration power-plants. Combustion of agricultural biogas in cogeneration power-plants is an environmentally friendly way to produce electricity and heat.

Organic materials are placed in sealed containers where the bacteria produce biogas during the anaerobic digestion process (normally 65% of methane and 35% of CO2). Usually agricultural biogas makes about 10% of gases causing the greenhouse effect. Methane evaporating from theorganic waste handled in agriculture can be collected for the use in gas engine cogeneration power-plants to produce electricity. The farms using this technology perfectly arrange own organic waste without polluting the environment and producing sufficient amount of electric energy and heat for the domestic need of their farms. Larger agricultural holdings sell the excess energy to local electric power networks.

Cogeneration of agricultural biogas is usually applied:

on pig breeding / feeding farms

on livestock feeding and milking farms

on poultry farms

on plant-growing and stockbreeding farms (mixed type)

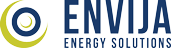

In normal agricultural biogas plant methane and CO2is generated during the decomposition of organic waste. To speed the process, the waste is heated to 38 °C - 56 °C. For the aeration of waste blowersare used.

Typical scheme of the operation of agricultural biogas processing facility of cogeneration power-plant:

Anaerobic digestion process reduces the harmful effects of waste and reduces chemical release of oxygen. This helps to protect the aquatic flora and fauna, as minimum content of separated oxygen is required for the survival of fish and other aquatic and microorganismsof underwater world. The bacteria involved in anaerobic digestion process eliminate unpleasant odourcausing compounds. Furthermore, during the process the eggs of flies causing many diseases are destroyed. Greatpart of organic nitrogen contained in waste is converted into ammonia. These are fertilizers widely used in agriculture.

BIO gas recovery power-plants

Biogas generators started to be built and used in Asian and African countries thousands years ago. At present, there are several millions of small (3-10 m3) of biogas reactors in China and India, satisfying the energy needs of private economy. Modern technologieswere created based on their experience;they have the latest knowledge of microbiology, energy equipment and process controls applied. The purpose of biogas power-plants has changed as well. Now they are built not only for the output of energy production from waste or biomass grown, but also for the improvement of the state of the environment and production of valuable fertilizers. Agricultural, industrial and residential organic waste less processed in modern biogas power-plants pollute the soil, water and air less. They destroy dangerous bacteria and viruses. Furthermore, they release unpleasant smells as well.

Anaerobic digestionof organic waste recycling is an excellent example of co-operation of mankind with the nature. Using such way of waste processing,the enormous amounts of liquid organic waste resulting from the human activities are decontaminated. Along with the principal, direct and environmental effect,additionally substantial power and none the less agricultural effects are obtained here.The production of biogas has already become a profitable business in economically developed countries of the world for many years.

Structure ofbiogas power-plant and technological scheme depend on various factors: the type and composition of raw materials,method of its delivery, type and sizeof bioreactors, process parameters, use of recycled substrate,amount and composition of produced biogas, type and quantity of energy conversion equipment andconsumers of produced energy. Raw material collection, preparation and transport equipment, storage of biogas produced by bioreactors, treatment and incineration plants, tanks for processed biomass, technological equipment controllers, electrical and thermal energy networks are installedin a classic biogas power-plant.

Processed biomass can be supplied directly to the biogas reactor by pipeline from the waste source (farm, production workshop) or be brought from other objects. Biomass ofdifferent types is mixed in the collection tank. The organic waste (slaughterhouses, oil or margarine) of high concentration and energy potential can be kept separately (in drums, containers) and supplied to the reactor in parts so as to control the amount of biogas produced.

Biomass processed in biogas reactors is a good fertilizer, rich in nutrients necessary for the plants: nitrogen, potassium and phosphorus. If mineral fertilizers are replaced with organic ones, additional benefit is received: energy consumption for the production and transport offertilizers is reduced, the environment is polluted less andsoil properties are improved. Besides, the biomass processed in bioreactors is more homogeneous and more evenly spread on the fields.

MWM Biogas project ENG

Reasons why it is worth using the BIO gas power-plants and cogeneration on farms

Alternative business branch, using the waste accumulated on farms

Fixed income selling the electricity produced

The farms are protected from overproduction (the production grown in very fertile year can be used for the generation of electricity rather than sell at low prices)

During the treatment of livestock and poultry manure in a bioreactor, part of nitrogen in organic compounds is converted into the form of ammonia, which can be easily assimilated by plants (content of ammonia nitrogen in degassed manure increases by 10-15%)

The seeds of weed are partially digested and their viability rate is reduced during the anaerobic process. So, ifdegassed manure is used for the fertilization of plants, their weediness is reduced.

The plants absorb nutrients from the degassed manurefaster.

Ifdegassed manure is used as fertilizer, plant leavesare not burnt off. Therefore, they can be fertilized during the growing season.

During the treatment of organic waste in bioreactor biological oxygen demand isreduced (BOD) by 80%, and chemical oxygen demand (COD) - by 50%. This means that harmful effect ofthe degassed substrate on the environment is significantly reduced.

Greenhouse effect is reduced. During the manure storage, anaerobic process occurs under natural conditions, and released methane enters the atmosphere, thereby increasing the greenhouse effect. It should be noted that methane increases the greenhouse effect by 21 times more intensively than carbon dioxide. While treating the manure in a bioreactor, the resulting methane does not get into the atmosphere,but is used for the satisfaction of energy needs.

A lot of pathogenic microbes die during the process. Therefore, the use of degassed manure for the fertilizationimproves the environmental sanitary condition at the same time.

The risk of contamination of groundwater with nitrates is reduced, as the plants absorb a larger amount of nitrogenous nutrients from degassed manure more quickly.

Unpleasant smell of degassed manure is reduced, because unstable organic compounds decompose during the anaerobic process

A great stimulus for the expansion of technology is the use of renewable energy sources in cogeneration power-plants. EU directives provide for additional measures to promote the production of energy from renewable sources –underlying connection to the system network, simplification of administrative procedures, award of grants in the form of fixedrates, tax exemptions, green certificates,etc.

The use of cogeneration on greenhouse farms

The use of cogeneration power-plants in greenhouses is a great way to use the products generated by gas engines at the maximum, i.e.:

the heat drawn from the engine cooling and exhaust systems and used for heating of greenhouse;

CO2exhaust gas, which is used for saturation ofgreenhouse air with CO2so as to stimulate the growth of plants;

electrical energy which is used to provide additionallighting of greenhouses, and surplus electricity is sold.

Typical scheme of the operation of cogeneration power-plant in greenhouses:

.jpg)

In this case, the engine exhaust gas cannot be routed from the gas engine exhaust system directly into the greenhouse due to toxic gases of fuel such as nitrogen oxides (NOx), carbon monoxide (CO) and unburned carbohydrates (CnHm) generated during the combustion process. These gases are the sources of air pollution causing acid rains and global warming. Moreover, they are toxic and harmful to the central nervous system and heart of human. Therefore, if you want to use these gases in greenhouses, they must be treated additionally, i.e. decontaminated. This requires the system of catalysts consisting of selective and oxidative catalyst.

In order to saturate the 2-hectare area of greenhouse air with sufficient amount of CO2,thegas engine cogeneration power-plant with capacity of approximately 1 MW must be installed.

The heat energy on the basis of hot water generated in a cogeneration power-plant is collected in isolated buffer tanks; control system distributes the heat via thepipelinesinstalled under the greenhouse as required. Thusrequired constant temperature ismaintained in the greenhouse.